Dual hour meters: Analogue Vs Quartz

Older Engine timers do not contain a timekeeping oscillator such as a pendulum or balance wheel, but instead counts the oscillations of the AC utility current from its power source to keep time. It consists of a small AC synchronous motor, which turns the clock’s dial through a reduction gear train. The motor contains electromagnets that create a rotating magnetic field which turns an iron rotor. The rotation rate of the motor shaft is synchronized to the utility frequency; 60 cycles per second (Hz) in North America and parts of South America, 50 cycles per second in most other countries.

“The frequency of the transmission system was, is and will be never stable at exactly 50Hz or 60 Hz for a reasonable amount of time, either leading or lagging depending on the generation, loading and other conditions of operation of the transmission system. The following regulations apply: Short term +3%/–5% frequency variation range and normal ±2% frequency variation range as defined by IEEE C50.13 and IEC 60034-3.”

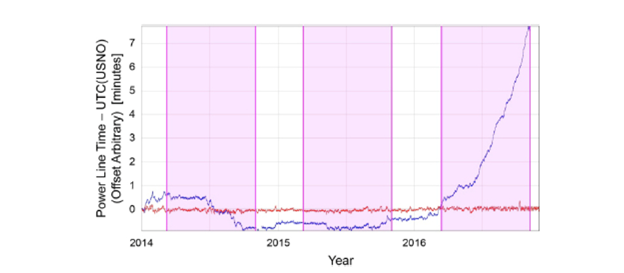

The over 7-minute time error that would have developed in electric clocks over much of N. America had they not been reset after the March 2016 switch to Daylight Saving Time and had TEC’s not been utilized. The Gridline frequency and voltage are also affected by large motors and generators in the plant. Many plants see brownouts and surges on a regular basis.

Quartz clocks are electric clocks that keep time by counting oscillations of a vibrating quartz crystal. They use modern low-voltage DC-powered circuitry, which may be supplied by a battery or derived from mains electricity. They are the most common type of clock today. Quartz clocks and watches as supplied by many manufacturers typically keep time with an error of a few seconds per week, although sometimes more. Inexpensive quartz movements are often specified to keep time within 30 seconds per month (1 second per day, 6 minutes per year). The lower error can be achieved by individual calibration if an adjustment is possible, subject to the stability of the oscillator, particularly with the change in temperature. Higher accuracy is possible at a higher cost.

For example, if the incoming power of the mechanical clock was coming in at an average of 59.8 Hz, there is a calculation that can be made to determine the amount of “loss” that is occurring due to a lower mean frequency.

Assuming a full year of this same loss, 29.2 hours of time would not be counted.

Quartz counts will lose about 6 minutes of counting on average per year.

This can be very serious if they are used to specify maintenance intervals as an analog timer understates the amount of time the engine has been run. This could potentially cause damage to the engines since they are running longer than the clock says. The cost of a good Quartz timer is low considering the damage a missed service or oil change may cause.

Source: Frequency NIST Paper

EngineBuzz

EngineBuzz