The What, When, and Why of “Spread” By Thomas Grant

What is Spread?

Spread – The sensitivity of the analog detonation meter expressed in Knockmeter divisions per octane number. What are the major components required to obtain Spread

- Sensor, D-1 pick-up, (Pressure transducer)

- Signal conditioning instrument – Detonation meter, 501 series

- Display – Knock meter (Weston or Metermod)

- Internal combustion engine

The What, When, and Why of “Spread”

D-1 Pickup – This is a Magnetostrictive-type transducer that treads into the engine cylinder and is exposed to combustion chamber pressure to provide an electrical signal that is proportional to the rate of change of cylinder pressure.

The Detonation Meter – Is a signal conditioning instrumentation that accepts the electrical signal from the detonation pickup and provides an output signal for display.

Knock Meter – Is a 0-100 division indicating meter that that displays the knock intensity signal from the detonation meter

Internal Combustion Engine

The four-stroke internal combustion engine has a combustion chamber, piston, and cylinder, where a fuel-air mixture is drawn in. The mixture is compressed by the piston and ignited, with a spark plug, and the rapid expansion of gases inside the cylinder forces the piston, which is connected to a crankshaft and flywheel, down. The crankshaft transfers the energy of the moving piston to other components, while the flywheel sustains the momentum of the crankshaft until the next combustion cycle takes place. They can control the intake of fuel, the timing of the ignition and the operation of the valves for the intake and exhaust cycles.

Terminology

Knock Intensity – The measurement of the level of knock.

Knock – Abnormal combustion, often producing audible sound, caused by auto-ignition of the air/fuel mixture.

Standard Knock Intensity – The level of knock established when a primary reference fuel blend of specific octane number is used in the knock testing unit at maximum knock intensity fuel-air ratio, with the cylinder height (dial indicator or digital counter readings) set to the prescribed guide table value. The detonation meter is adjusted to produce a Knockmeter reading of 50 for those conditions.

Why is Spread so Important?

- It gives a reference point for electronic sensitivity

- It provides the accuracy for octane determination

- Defines the engine’s stability

Can Spread become Biased?

Yes

What are some causes of “BIASED” Spread?

- Electrical Interferences

- EMI – Electromagnetic Interference

- RFI – Radio Frequency Interference

- Dirty Power

- Electrostatic Discharge – static electricity

- Faulty Electronic Detonation Meter Components

- Engine not bonded correctly

- Malfunctioning or damaged equipment

- Pick-up cable

- Detonation Meter

- Pick-up – D1

- Knock Meter

- Cylinder

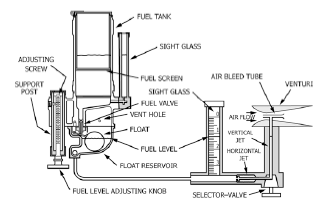

- Carburetor

- In proper auto-ignition of the air/fuel mixture (Most Common problem found in octane facilities today)

Questions

What is the proper mixture for fuel to air when obtaining max knock intensity or maximum burn?

Approximately 15 parts of air to 1 part fuel

Max Knock Intensity shall occur within the sight glass range of 0.7 “– 1.7”

Fuel to Air Mixtures

The stoichiometric mixture for a gasoline engine is the ideal ratio of air to fuel that burns all fuel with no excess air.

For gasoline fuel, the stoichiometric air-fuel mixture is about 15:1. (for every one gram of fuel, 15 grams of air are required)

The fuel oxidation reaction is:

- An air mixture greater than ~15 to 1 is considered a lean mixture

- Less than ~15 to 1 is a Rich mixture

The given or perfect “test” fuel for a gasoline engine is a mixture of n-heptane and iso-octane.

In reality, most fuels consist of a combination of heptane, octane, a handful of other alkanes, plus additives including detergents, and possibly oxygenators such as MTBE (methyl tert-butyl ether) or ethanol/methanol. These compounds all alter the stoichiometric ratio, with most of the additives pushing the ratio downward (oxygenators bring extra oxygen to the combustion event in liquid form that is released at the time of combustions; for MTBE-laden fuel, a stoichiometric ratio can be as low as 14.1:1). Vehicles that use an oxygen sensor or another feedback loop to control fuel to air ratio (lambda control), compensate automatically for this change in the fuel’s stoichiometric rate by measuring the exhaust gas composition and controlling fuel volume. Vehicles without such controls (such as most motorcycles until recently, and cars predating the mid1980s) may have difficulties running certain fuel blends (especially winter fuels used in some areas) and may require different jets (or otherwise have the fueling ratios altered) to compensate.

Can you set spread initially at a 90 octane level, and use that setting for the entire octane range?

No

Spread Setting

Detonation meter spread set to 12-15 K.I. Divisions per O.N. at the 90.0 O.N. level will typically provide suitably optimized spread setting for the range of 80.0 – 100.0 O.N. without resetting

Remember: It is very important to have the Correct spread

Is there a change in the electronic signature, being produced by the D-1 pick-up, at various octane levels?

Yes

Spread Characteristic—Detonation meter spread or sensitivity (K.I. divisions per O.N.) is a function of the detonation meter SPREAD dial settings. Regardless of the spread dial setting, however, K.I divisions per O.N. varies as O.N. level is changed because of the engine operating characteristics and the nature of the O.N scale. The effect of spread variation with O.N. level for a selected spread dial setting is illustrated in FIg. A4.6. In the 80 to 100 O.N. range, the maximum amount of spread achievable can be greater than desired because of K.I. reading may become too unstable for satisfactory observation (excessive signal-to-noise ratio). However, as the figure demonstrates, a workable spread setting can be selected to permit rating over a wide O.N. range. Use of a spread set to approximately 12 to 15 for the 90 O.N. level typically achieves this condition and reduces the frequency of making spread dial changes when testing sample fuels in the commercial fuel O.N. range. When testing samples at levels below 80 O.N., spread naturally decreases and spread dial changes are desirable to maximize sensitivity for optimum measurement resolution at these lower O.N. levels.

EngineBuzz

EngineBuzz