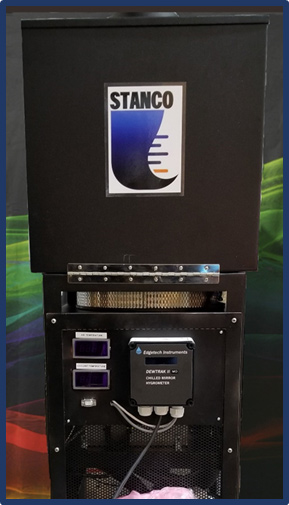

Humidifying Intake Air Tower

StanCo Scientific Humidifying Intake Air Tower with DewTrak II-MO™ Control

We have extensive experience with closed-loop cooling systems in other instrumentation types. We took that knowledge and applied it to carburetor cooling issues to use with Octane engines. To further meet the ASTM requirements, a heavy-duty vaporizer was introduced to ensure that the air stream to the engines is within the required 25-50 grains per pound of dry air. To measure this humidity, a chilled mirror hygrometer is installed to provide constant and accurate readings.

Cooling:

- A 4,000-milliliter cooling system used to control the operating temperature of carburetors and heat exchangers. Its semi-sealed design minimizes microbial growth within the cooling system due to no introduction of air after the initial setup.

- Powerful and easily maintained coolant pump

- The cooling system monitored and temperature-controlled through the use of solid-state relays.

- Integrated brass bypass valve to isolate carburetors when cooling is not required.

- Temperature monitoring of tower’s output air-humidity mixture

Vaporizer:

- Automated vaporizer with 6-liter reservoir

- Reservoir has an integrated auto-fill valve for ease of use. Simply attach to an existing water line

- Lifespan of vaporizer factory-rated at 5,000+ hours if maintained properly. Quality of tap water and neglecting to do maintenance every 3-6 months will reduce the vaporizer’s longevity.

- No LED design on the vaporizer ensures zero-leak operation and limited algal growth. All vaporizers are TUFF coated for increased reliability and carry a 2-year warranty

- 500 milliliters per hour of water consumption potential through vaporization of 5-micron sized droplets.

- Higher consumption vaporizers available for specific needs of ASTM requirements

- Swirled air vanes in the outlet to promote homogenous air-humidity mixture to the engine

Humidity Control:

- The Edgetech Instruments DewTrak II-MO™ dew point/humidity transmitter is an optical chill mirror hygrometer designed to continuously measure the moisture content in gases. The instrument is powered by 24Vdc.

- The DewTrak II-MO™ uses the chilled mirror dew point temperature condensation principle to determine the water vapor concentration in gas mixtures, and a platinum resistance thermometer to accurately measure that temperature. Outputs include 4 to 20mA, 0 to 5 Vdc, or 0-10Vdc and an RS232 serial port as well as electrically isolated relay contacts.

- NEW! Model DX primary method chilled mirror dew/frost point sensor with an integral

- PRT temperature sensor. It offers a wide operating range and improved temperature stability.

- 4 wire PRT measurement for Dew Point and AT (optional)

- ±0.2°C Accuracy for both Dew Point and Temperature

- Long term stability and repeatability

- RS232, bi-directional, Serial Output for ease of reprogramming with a stock port on the side of the instrument

- Electronics housed in IP65 enclosure (Wall Mount)

- Aluminum housing for other configurations

- 2 analog outputs (4-20mA / 0-5Vdc to 0-10Vdc selectable)

System:

- Controls for humidity and temperature – 24 volts DC

- Cooling and vaporizing systems – 125 volts AC

EngineBuzz

EngineBuzz